The automation in the construction industry is less developed when compared

to other industries. Traditional methods on house-building are usually based

on manual techniques which are slow and expensive. The productivity of construction

industries can be improved by using new materials, new construction methods

and new information technology techniques. The aim is not only to increase

productivity, but also to improve work safety and hygiene conditions. These

systems will increase the quality and the customer satisfaction.

The main difficulties that focus the automation construction industry are:

non-structured workspace, the building diversity, the number and variety

of construction processes, the volume and weight of pieces to handle, the

necessity of qualified workers and the exchange of information between the

different stages (design, planning, transport, erection, maintenance, etc.).

The integration of activities should be the major objective to increase benefits.

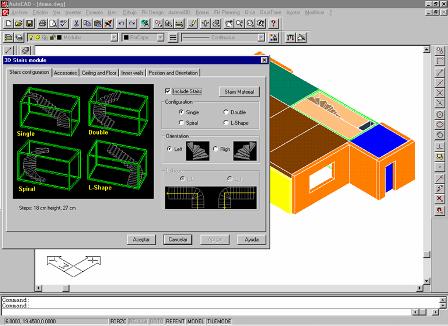

This work is part of an integrated project that deals with automation in

the construction and, in particular, with the erection of modular buildings.

The buildings will be assembled by placing prefabricated modules with robots

or automated cranes. A Computer Integrated Construction (CIC) architecture

has been proposed to achieve modular construction. Design, planning and simulation

tools have been integrated under a common graphical user interface. In this

work, several design and animation tools have been developed. In parallel

a planning tool has been developed to calculate the modules assembly sequence

from the design data.

The first design tool guides the user step by step to place modules into

design from a library of parametrised modules, created specially for this

purpose. The second design tool permits to obtain in an automatic way the

dimensions and position of the modules that are needed to construct a building

starting from the traditional architectural design. The selection of the

modules will be carried out responding to several criteria: minimum number

of modules, minimum number of different modules, module size and shape limitations,

etc.

Simulation and animation tools have also been designed and implemented within

the design CAD itself, as part of this thesis. These tools consist of, a

gantry crane simulator, a tower crane simulator and a program editor for

both. The simulators can be moved manually or can be programmed to execute

the task written in a specific crane language which has been developed. This

language is used to program the real prototype of gantry crane in the laboratory.

Programs can be written with the program editor or automatically generated

by a planning tool.